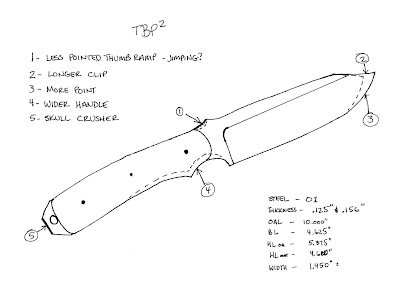

The first thing was a thumb ramp above the handle. This gives your thumb a place to rest when you are going at it. Jimping will be added for better traction on the thumb ramp.

I like a slightly longer clip. This flat clip will still have plenty of steel behind the point for maximum penetration and integrity.

Next, my belief is the knife is being designed for SHTF work so it needs some point to be able to open soup cans or a car door, drill a hole in plywood and stab into anything.

Mike first mentioned to me about a beefier handle at the blade/handle junction. Comfort and grip are my main concerns and I think this works well.

Last is a little Skull Crusher at the end to use for breaking skulls or other breakable stuff...but mostly skulls.

I cut out two blanks for the prototypes. These aren't the steel we plan to use but what I had on hand at the moment. One was Aldo's 1095 and it was .150" thick, close to the 5/32" we'll use. The other was Aldo's 1084, it was .200" thick. At first Mike wanted the knives to be 3/16" thick so I'm trying a thick one. My thought on that is if we use a tougher steel we can make it thinner and stronger. The O1 is on order and will be used after the prototypes have been looked at and checked for any design changes.

Steel will be ordered in .125" and .156" thicknesses and will be a choice for anyone that orders one. This will take a while to get it all right. Can't be sure when knives will be available.

Here are the blanks cut out and profiled to shape.

This is after the initial grinding. Next is drilling any holes in the handle area and then on to heat treating.

Hopefully I will get heat treating done this week and have a chance to get close to finishing them this weekend. Stay tuned for the next installment of TBP-AK EDC. Now you can follow my posts by signing up for email updates. It is about time I got that going.

No comments:

Post a Comment