It has been an itch that hasn't been scratched for a while at the homestead. That itch is Home Brewing.

I can faintly recall the last batch of beer I made, but it's been a while. Home brewing is one of those things that thoroughly satisfies my soul. The week was started by making a 3 gallon batch of Mead or Honey Wine.

First thing to do is aquire some pure Tennessee spring water from our friends at Dunmire Hollow. Eighteen gallons was brought home to use in all my brewing. Mead is simple to make and requires only a few ingredients. I started out with about six quarts of locally produced honey. That was added to heated spring water to dissolve it all. That was added to a carboy with more spring water in it along with two cut up oranges and one cut up lemon. After the carboy was filled to the proper amount, champagne yeast was pitched.

It only took an hour or so to take off and start bubbling furiously. The color of the liquid has steadily lightened over the course of a few days. Meads can take a long time to ferment out and they are generally "Green" for 6 months or more. They get better with age and this one is a basic recipe. I'm looking for a light clean taste out of this one.

Having stuff overflowing from our freezer I decided to make a batch of wine to go along with the mead. This was to be blackberry/blueberry wine. After thawing the precious nectar prodcing berries, they were gently massaged to release the wonderous juices stored inside. Wine is also very easy to make and both of these batches were done to get me ready for brewing the double batch of beer.

Using my 5 gallon stainless steel pot, I heated up a few gallons of spring water enough to dissolved 10 pounds of common white sugar. This was added to a fermenting bucket with more spring water, the juice from all the berries and a nylon bag with the berries themselves in. This "Must" is left for 24 hours with a towel covering it before the yeast is pitched.

After the yeast is pitched, the buckets lid is put on, with an airlock in it. From that point on the must is stirred and the berries squished daily until primary fermentation is complete. Then it will be racked into another carboy for long term storage and clarifying.

I say long term storage because I still have a few gallons of the last fruit wine I made. It can sit for a while before I bottle it in gallon jugs for use.

And what all this prior work has led up to is...Home Brew!!!

Friday after work was when the real work started. Wine and mead are very easy. Brewing beer can be as easy or difficult as you want it to be. I prefer to brew partial mashes. That means using grains along with extracts to impart qualities to the brew that 100% extract beers can't achieve.

Grains were put into a pot of spring water, over a single electric heating element. This "Mash" is slowly heated to around 155F. At that time the heat is reduced and it is allowed to steep, like a tea, for 30-45 minutes. While that is steeping, I heated more spring water to 170F. At the end of the steep cycle I pour the mash into a nylon bag inside a food grade bucket. The 170F water is poured over the grains to transform it into a virtual smorgasbord of sugars for the yeast to consume, and turn into alcohol.

That stained liquid is put into the brew pot and heated up over a propane burner. Once the temp of the liquid is up to about 190F I take the pot off the heat and add my liquid malt extract (LME) . Taking it off the heat ensures that you won't burn the malts as you put them in. You want to be sure everything is dissolved before you start up the burner again.

When your wort begins to boil, it is time to put in your first batch of hops and start your 1 hour timer. The first hops are for bittering the brew. This helps balance out the sweetness of the malt and hops also act as a preservative. So get Hoppy. I add my hops straight to the boil, as it imparts more hoppiness to the brew, so be careful this is where you could possibly have the dreaded "Boil Over". Many folks use a muslin hops bag, which will keep your beer cleaner, help the boil over and be able to remove the spent hops when done.

After 30 minutes I add my second batch of hops to the boil and with 12 minutes left I add my last batch of aroma hops.

When the brew time is over, you must cool down the wort before you can add it to the carboy and before the yeast can be pitched. I have a wort chiller which attaches to a faucet and cold water running through it cools it down. Most of the time I just put the whole brew kettle into a sink or tun and use cold water to cool it down. After the pot is cool enough to hold your hand onto for 10 seconds or more it's time to take the sanitized carboy and add cool liquid to it. Enough to come up 3 or 4 inches in the bottom. You never add hot wort to the carboy without cool water in first. When you've put your wort in, bring it up close to the top of the jug allowing headspace for fermentation bubbles.

Alright at this point you have a carboy full of wort. The next step is to cover the top of the carboy, rput your foot on a chair, and lay the carboy on your leg with your hand and a stopper covering the hole. Now shake vigorously for a good minute or two. This oxygenates the wort for the yeast to do their lovely work. After shaking it is time to add the yeast. I used a starter, so it was poured in and given a gentle shake or two to distrtibute the yeast.

Last thing to do is attach a sanitized stopper and airlock to the top and wait for fementation to take off. Waiting can really stink. When I went to the shop to close up last night one of the two carboys was already bubbling, slow but sure. When I went out this morning both batches were going like crazy. One of my favorite thingd is watching the yeast swirling around inside the bottles. Sometimes moving so much it looks as if someone was physically shaking it.

These will sit in the primary fermenter for about two weeks. Then they'll be racked into secondary fermenters for...who knows how long.

Brew On My Friends! There's more to life than just work.

Hopefully this will motivate me to get back to knife work.

Saturday, May 11, 2013

Monday, April 15, 2013

Knife Update

The knife I sent out at the end of February, to a great customer, was put to good use over the last weekend. Looks like two nice gobblers fell to Caleb.

If blood makes you squeamish stop right here.

If the sight of blood on a new knife blade doesn't bother you take a look.

What an an awesome way to break in that new knife. Love that Wild Turkey. Congratulations!

If blood makes you squeamish stop right here.

If the sight of blood on a new knife blade doesn't bother you take a look.

What an an awesome way to break in that new knife. Love that Wild Turkey. Congratulations!

Tuesday, March 26, 2013

TBP EDC

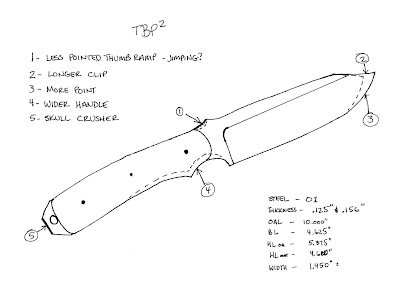

Whoa! I best get something on here about the upcoming knife "The Backyard Pioneer EDC". Mike Prunty at TheBackyardPioneer.com and I have started working on a knife together. He originally liked the Camp knife listed here. We decided to make some changes to that design. I actually made an outline of the Camp knife and sent it snailmail to Mike. He wanted to incorporate a few things into the design. Mike's ideas included a thicker steel, a clip point and a thumb ramp. After looking at his ideas, I decided to make some slight changes. His design is shown in the fist diagram and by the dashes and my changes in the second drawing.

The first thing was a thumb ramp above the handle. This gives your thumb a place to rest when you are going at it. Jimping will be added for better traction on the thumb ramp.

I like a slightly longer clip. This flat clip will still have plenty of steel behind the point for maximum penetration and integrity.

Next, my belief is the knife is being designed for SHTF work so it needs some point to be able to open soup cans or a car door, drill a hole in plywood and stab into anything.

Mike first mentioned to me about a beefier handle at the blade/handle junction. Comfort and grip are my main concerns and I think this works well.

Last is a little Skull Crusher at the end to use for breaking skulls or other breakable stuff...but mostly skulls.

I cut out two blanks for the prototypes. These aren't the steel we plan to use but what I had on hand at the moment. One was Aldo's 1095 and it was .150" thick, close to the 5/32" we'll use. The other was Aldo's 1084, it was .200" thick. At first Mike wanted the knives to be 3/16" thick so I'm trying a thick one. My thought on that is if we use a tougher steel we can make it thinner and stronger. The O1 is on order and will be used after the prototypes have been looked at and checked for any design changes.

Steel will be ordered in .125" and .156" thicknesses and will be a choice for anyone that orders one. This will take a while to get it all right. Can't be sure when knives will be available.

This is after the initial grinding. Next is drilling any holes in the handle area and then on to heat treating.

Hopefully I will get heat treating done this week and have a chance to get close to finishing them this weekend. Stay tuned for the next installment of TBP-AK EDC. Now you can follow my posts by signing up for email updates. It is about time I got that going.

The first thing was a thumb ramp above the handle. This gives your thumb a place to rest when you are going at it. Jimping will be added for better traction on the thumb ramp.

I like a slightly longer clip. This flat clip will still have plenty of steel behind the point for maximum penetration and integrity.

Next, my belief is the knife is being designed for SHTF work so it needs some point to be able to open soup cans or a car door, drill a hole in plywood and stab into anything.

Mike first mentioned to me about a beefier handle at the blade/handle junction. Comfort and grip are my main concerns and I think this works well.

Last is a little Skull Crusher at the end to use for breaking skulls or other breakable stuff...but mostly skulls.

I cut out two blanks for the prototypes. These aren't the steel we plan to use but what I had on hand at the moment. One was Aldo's 1095 and it was .150" thick, close to the 5/32" we'll use. The other was Aldo's 1084, it was .200" thick. At first Mike wanted the knives to be 3/16" thick so I'm trying a thick one. My thought on that is if we use a tougher steel we can make it thinner and stronger. The O1 is on order and will be used after the prototypes have been looked at and checked for any design changes.

Steel will be ordered in .125" and .156" thicknesses and will be a choice for anyone that orders one. This will take a while to get it all right. Can't be sure when knives will be available.

Here are the blanks cut out and profiled to shape.

This is after the initial grinding. Next is drilling any holes in the handle area and then on to heat treating.

Hopefully I will get heat treating done this week and have a chance to get close to finishing them this weekend. Stay tuned for the next installment of TBP-AK EDC. Now you can follow my posts by signing up for email updates. It is about time I got that going.

Tuesday, March 19, 2013

New Offerings

There are some things that I have wanted to offer for a while and with the help of my lovely wife we put together some Personal Survival Kits or PSK's. These handy little kits are made to stuff into a pocket, pack, purse or whatever just in case you may have to spend an unintended evening in the woods.

We decided that the contents of these kits would have to fit into an Altoids tin. While spending one night in the woods shouldn't be anything major, it can be very disorienting and lead to any number of problems. Hunters, fishermen, backpackers, hikers or anyone that goes out to the woods should be prepared with a minimum of gear. The biggest issue when someone is lost or turned around in the woods is their own self. They tend to doubt their abilities and then their gear. With just a few items you can keep your mind focused on keeping yourself as comfortable as you can for your overnight stay. A fire will help you to stay warm and ease your mind.

The kits have the basics for starting a fire, water purification, navigation, repairing torn clothing or packs, first aid, fishing and signaling. I will offer these with or without my P.A.T.(Pats Altoids Tin) knife and I'll also keep emergency blankets on hand.

Just as you make preparations for most things you do, this gives you a little assurance that you have at least minimal gear with you when you visit the out-of-doors. PSK's don't stop things from happening but can give you some peace of mind that a little incident doesn't have to turn into a major rescue mission. Thousands of folks each year get stuck outdoors when weather hits unexpectedly, lost or injured. Don't get caught empty handed.

For fun Leslie put together a Mini PSK too. It has less of everything, but most of the same items as the PSK. Can you see the cute little mini knife at the bottom? It is made to cut. All of this stuff fits into a mini Altoids tin. It is crazy!!!

We decided that the contents of these kits would have to fit into an Altoids tin. While spending one night in the woods shouldn't be anything major, it can be very disorienting and lead to any number of problems. Hunters, fishermen, backpackers, hikers or anyone that goes out to the woods should be prepared with a minimum of gear. The biggest issue when someone is lost or turned around in the woods is their own self. They tend to doubt their abilities and then their gear. With just a few items you can keep your mind focused on keeping yourself as comfortable as you can for your overnight stay. A fire will help you to stay warm and ease your mind.

The kits have the basics for starting a fire, water purification, navigation, repairing torn clothing or packs, first aid, fishing and signaling. I will offer these with or without my P.A.T.(Pats Altoids Tin) knife and I'll also keep emergency blankets on hand.

Just as you make preparations for most things you do, this gives you a little assurance that you have at least minimal gear with you when you visit the out-of-doors. PSK's don't stop things from happening but can give you some peace of mind that a little incident doesn't have to turn into a major rescue mission. Thousands of folks each year get stuck outdoors when weather hits unexpectedly, lost or injured. Don't get caught empty handed.

For fun Leslie put together a Mini PSK too. It has less of everything, but most of the same items as the PSK. Can you see the cute little mini knife at the bottom? It is made to cut. All of this stuff fits into a mini Altoids tin. It is crazy!!!

Rescue Me

In an earlier posting about the kitchen knives I have accumulated, more than one was a rescue knife. By rescue knife I mean it had been abused in the past and left for dead. I don't find good ones in that shape very often but when I do I snatch them up and give them a little TLC. The two rescue knives in the pic are the 2nd up from the bottom on the right side, and the 2nd down on left side.

This rescue knife is the 2nd down on the left. It is a J. A. Henckels 10" Chef knife. New, this knife probably went for $100. I got it at a thrift store for $0.50. You can't really see in this picture how badly it has been treated, but trust me, it was in bad shape. It looks as though someone took it to a grinding wheel thinking they could sharpen it that way.

Here you can get an idea of how it was treated. There are deep scratches, scuffs and grind marks going every which way. The edge was damaged in places and there was no way this could be used in the state it was in.

So the first thing I do is make a plan and try to stick to it. I look it over and see that the cutting edge is uneven but the spine is straight. The tip has been ground down and there are battle scars on the spine. The guard/bolster area needs to be taken down a bit for the knife to cut properly. As you can see in this pic I have drawn a line at the tip that I will cut off at the portaband. While cutting it I dipped it in water many times to keep the steel cool. After cutting the tip off it's time to take it to the knife grinder. When the tip was cut it left the area thicker than the tip should be. My first step is to thin the tip down so it flows with the rest of the blade. I can't tell you how wet my hands got grinding this blade. It went into water after every second or two of grind time and I touched it to make sure I didn't let too much heat build up and ruin the heat treating.

This was a very slow process and after an hour and a half of grinding it looked pretty good. Unfortunately I had to grind off the makers mark but it had to be done. I turned my attention to the handle which had some scarring. First I tried to buff the handle but it instantly caused friction burns. Next I got out the sandpaper and went at it with that. It will not have the shiny handle it once had but it will still feel good in the hand.

I notice the edge isn't as rounded, when compared to my 8" Henckels chef knife. The edge is more like that of a Sabotier. From the handle, the edge is fairly flat 75% of the way to the tip. It should perform well in the kitchen though.

It needs to be sanded a little more to make everything nice and even looking. Then it will get a good sharpening. At that point it will be ready to give away to some unsuspecting victim...I mean to one lucky reader of The Backyard Pioneer.

_________________________________________________

There was a minor setback with the Give Away knife. It seems to have a crack in the blade close to the handle. I noticed it as I was hand sanding the blade. A line kept showing up perpendicular to the edge as the 600 grit wet/dry sandpaper went over it. After seeing it happen a few times I turned the blade over and tried on that side. The line was about 12mm long and went to the edge and around the other side the same distance. Looking online, I found J. A. Henckels website, printed out their customer relations information and packed the knife up to send back to them. It went in the mail on March 26th. Hope their customer service is as great as their knives are. I informed them that this knife was going to be given away and their reputation was on the line.

When I hear something I will update the post and proceed from there.

Monday, March 18, 2013

Show Season Begins

The first of the season runs Friday March 22nd through Sunday March 24th in Linden, Tennessee. This is a good show with lots of people attending. Here's the low down on it:

LINDEN'S 5th ANNUAL BLOOMING ARTS FESTIVAL: WEEKEND EVENT FEATURING ARTS, CRAFTS, FOOD, AND LIVE CONCERT

LINDEN'S 5th ANNUAL BLOOMING ARTS FESTIVAL: WEEKEND EVENT FEATURING ARTS, CRAFTS, FOOD, AND LIVE CONCERT

Fire, glass, wood, antique fiber, molten metal, paint splatter, bungee jumping, live music and street theater dance!With an outstanding slate of events and interactive exhibitions, Linden's 5th Annual Blooming Arts Festival promises to be a spectacular kaleidoscope of fine arts, crafts, and performances that are all at once "family friendly" and focused on "audience participation"...while also offering food, music, kid's activities, and an element of spontaneous fun for all!

The 3 day event runs from 12am-5pm on Friday, March 22, 10am-8pm on Saturday the 23rd and 12-5 on Sunday, March 24th,featuring interactive artist demonstrations in blacksmithing, fiber art, , painting, theatre, and music of multiple genres.Demonstrating artists and performers include local and regional artists and artisans.Food will be abundant provided by local eateries and street vendors. Guests can tour the Linden Art District, and the Historic Commodore Hotel featured in recently on television and in magazines.

Approximately 100+ exhibiting artists will present items such as wood carved bowls, totem poles, hiking sticks, pottery, clay figures, stained glass, weaving's, jewelry, baskets, quilts, painted feathers, portraits, photographs, paintings, dolls and gourds.There will be live music on the square all day and the Saturday Night Concert, starting at 5:30, featuring Tara Tinsley and Joey Hyde,sponsored by First Bank, will surely get the town rockin'!

Linden is in final stages of its downtown revitalization and has a new streetscape including widened brick sidewalks, new streetlights and landscaping completing Linden's "renaissance" transformation. Linden's Mayor Jim Azbill, likes to tell all visitors to enjoy while "the paint is still

wet!"

wet!"

The Blooming Arts Festival is part of an effort to bring attention to the rich cultural, artistic, and historic heritage of the community, and has grown into a regional signature event attended by thousands. In continuing a nod towards technology, there will be a drawing for an iPad giveaway, sponsored by the Bank of Perry County, as part of a social media campaign. Participants need to become Facebook fans of the Blooming Arts Festival and register at the festival.

The 2013 Blooming Arts Festival has expanded not only in number of days, but also includes indoor and outdoor venues throughout Linden's downtown, with performers and demonstrating artists mixed within exhibit locations. A Quilt show, beauty pageant, large antique faire and a live concert on Saturday

Night make the first weekend of spring a jam packed not to be missed event.Participating artists are excited about their media, and eager to share information and encourage hands-on activity. Artist listing's, and a schedule of events will be available at the event's Welcome Booth. Festival attendance

and parking is free. For further information please go to www.bloomingartsfestival.org

Stop on by and say Howdy to Leslie and I as we welcome each and every person that stops by the booth. We will be there Friday and all day Saturday. Unfortunately we can't be there on Sunday.

Sunday, March 17, 2013

KMG Upgrade

So I finally went ahead and ordered a pair of 3-step pulleys from McMaster-Carr for my KMG grinder. It has been something on my mind for at least three years.

The reason for it is to be able to control the speed a little bit. Now I could have gone with a Variable Frequency Drive (VFD) and new DC motor to make it infinitely adjustable, but I did not want to spend $900 to do so. Instead I purchased a 6213K73 with 5/8" bore and a 6213K73 with a 3/4" bore to fit my motor and KMG drive wheel, respectively. The pulleys have 2", 3" and 4" wheels so I can get 3 speeds from a one speed motor by moving the belt from one tier to the next. They set me back a whopping $45 including shipping

There are many times when I want to slow the machine down. When working with materials like purpleheart and a few others, the fast speed burns the oils in the wood. Then it has to be sanded again, usually by hand, to get the dark coloration off. I'm sure this upgrade will pay for itself rather quickly. All totalled I have about $65 in this upgrade. Not bad when compared to $900.

First thing I did after ordering the 3-step pulleys was to clean off my grinding table. Dang there was stuff on that table that I haven't seen in years. Luckily the layer of dust was protecting everything.

Next was to take the motor off the bench and measure it all up and drill holes for the motor. My plan is to mount the motor to a piece of 3/4" plywood. Hinges will be attached to one side so the weight of the motor will keep a constant tension on the link belt.

The old pulleys were taken off of the motor and drive wheel with a gear puller. New pulley is attached to the motor in this picture. The other pulley was put on the KMG drive shaft.

From that point I had to attach the plywood base to the grinding table and remount the motor square to the grinder. I ordered 3 feet of link belt to replace the v-belt that was transferring the power from the motor to the grinder. The new link belt really makes a significant difference in the way the machine runs. V-belts will retain humps in the belt which makes things run bumpy. The link belt can be made any size by adding or subtracting the small links. So it was easy to make it the right size. With regular v-belts if you don't have the right size you end up going back and forth to the supply store to get the right one. This takes the guesswork out of the equation.

This upgrade was way easier than I thought it would be. It's something I should have done a long time ago and will make life a little easier at the old grindstone. Everything runs so smoothly now that I can't wait to grind some blades on it. I'll let y'all know how it works.

The reason for it is to be able to control the speed a little bit. Now I could have gone with a Variable Frequency Drive (VFD) and new DC motor to make it infinitely adjustable, but I did not want to spend $900 to do so. Instead I purchased a 6213K73 with 5/8" bore and a 6213K73 with a 3/4" bore to fit my motor and KMG drive wheel, respectively. The pulleys have 2", 3" and 4" wheels so I can get 3 speeds from a one speed motor by moving the belt from one tier to the next. They set me back a whopping $45 including shipping

There are many times when I want to slow the machine down. When working with materials like purpleheart and a few others, the fast speed burns the oils in the wood. Then it has to be sanded again, usually by hand, to get the dark coloration off. I'm sure this upgrade will pay for itself rather quickly. All totalled I have about $65 in this upgrade. Not bad when compared to $900.

First thing I did after ordering the 3-step pulleys was to clean off my grinding table. Dang there was stuff on that table that I haven't seen in years. Luckily the layer of dust was protecting everything.

Next was to take the motor off the bench and measure it all up and drill holes for the motor. My plan is to mount the motor to a piece of 3/4" plywood. Hinges will be attached to one side so the weight of the motor will keep a constant tension on the link belt.

The old pulleys were taken off of the motor and drive wheel with a gear puller. New pulley is attached to the motor in this picture. The other pulley was put on the KMG drive shaft.

From that point I had to attach the plywood base to the grinding table and remount the motor square to the grinder. I ordered 3 feet of link belt to replace the v-belt that was transferring the power from the motor to the grinder. The new link belt really makes a significant difference in the way the machine runs. V-belts will retain humps in the belt which makes things run bumpy. The link belt can be made any size by adding or subtracting the small links. So it was easy to make it the right size. With regular v-belts if you don't have the right size you end up going back and forth to the supply store to get the right one. This takes the guesswork out of the equation.

This upgrade was way easier than I thought it would be. It's something I should have done a long time ago and will make life a little easier at the old grindstone. Everything runs so smoothly now that I can't wait to grind some blades on it. I'll let y'all know how it works.

Subscribe to:

Posts (Atom)